Firearm Bedding

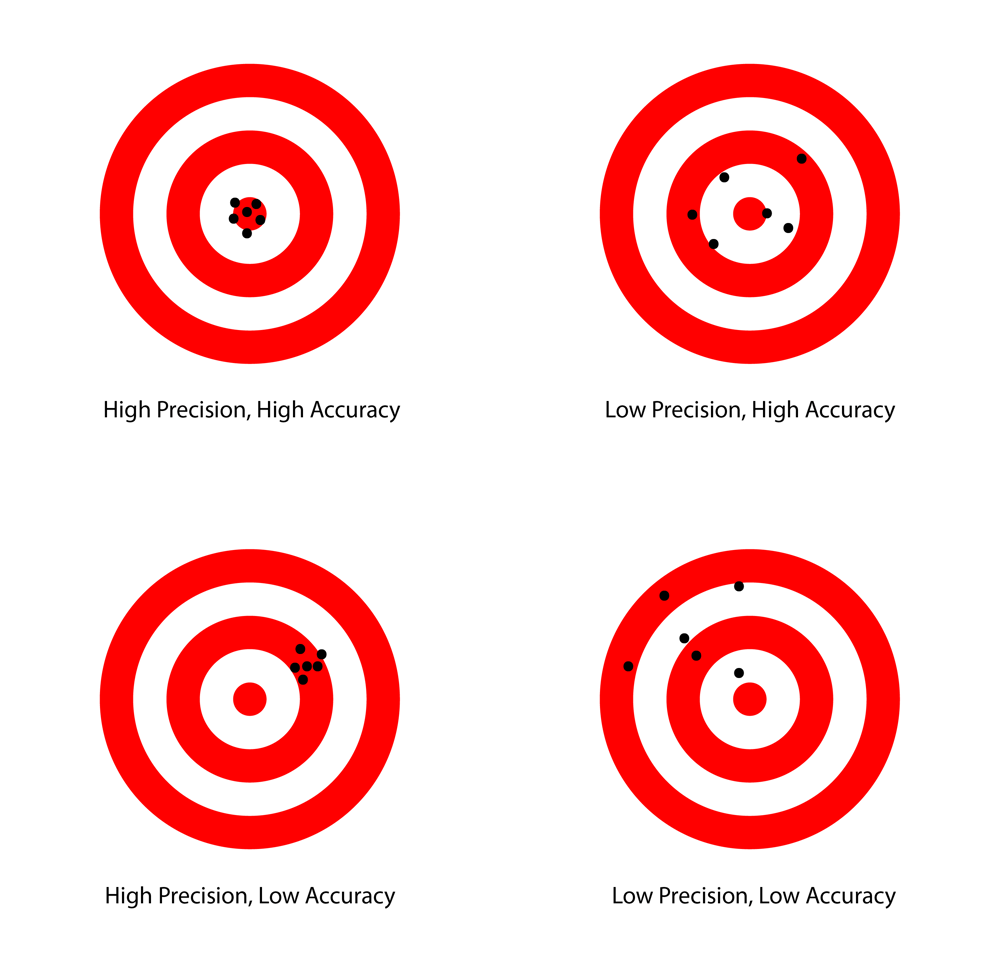

Rifle bedding is a process of providing a rigid and consistent foundation for a rifle’s operational components, by creating a stable and close-fitting bearing surface between the gun’s functional parts and its support part that do not deform with pressure or shift under the shear stress of the recoil from firing. The receiver and the stock are sometimes fastened indirectly through an intermediate piece (usually made of rigid materials such as aluminum alloy) known as a bedding block, which multifunctionally serves as a larger pillar, a bedding surface and even recoil lugs. The contact interface on the stock may also be substituted by a metallic bedding frame known as a chassis, which is either embedded within the stock, or even completely replacing the stock like the lower receiver on many modern modular semi-automatic rifles. The goal is to achieve high precision and high accuracy.

I offer two forms of bedding, Glass and

Pillar:

Glass bedding involves molding an epoxy-based material onto the stock to fill-in any gaps within its contact surface to the receiver.

Pillar bedding is inserting metal cylinders (which act as compression members) around the action screws to reduce compressive shifting.

There are sever types to choose from, depending upon the rifle, barrel, and stock type:

Full contact bedding of the action with the barrel floated.

Full contact bedding of the action and the barrel.

Full contact bedding of the action with a pressure-bearing pad for the barrel.

Pillar bedding of the action with the barrel floated.